Assembly and Commissioning

we understand that professional installation is essential for the optimal performance of your air pollution control system and industrial fans. Our experienced technicians and assembly specialists ensure fast, accurate installation and commissioning to get your systems up and running smoothly from the very beginning. Whether it’s an air pollution control system or industrial fan, our team brings extensive knowledge of assembly processes, site management, and monitoring to every project, ensuring precise execution at every step.

Correct commissioning is crucial to achieving maximum efficiency and performance in your air pollution control system. Our specialists not only ensure that every component functions as intended but also fine-tune each system for peak performance. We provide expert support to ensure your air pollution control system is seamlessly integrated into your existing processes, whether it’s the installation of industrial fans or air purification plants, ensuring long-term reliability and optimal operation.

Engineering Services

Discover our expertise in the development, design, and optimization of industrial fans and air pollution control systems. At Air Fractal, we specialize in providing high-quality engineering solutions for air pollution control systems and industrial fans. As experienced manufacturers, we understand the unique challenges our customers face in meeting specific operational requirements. Our engineering services allow you to leverage our expertise to address technical challenges and develop customized solutions tailored to your needs.

From initial planning and design through to commissioning and ongoing maintenance, we offer end-to-end support to help you achieve high-performance, reliable air pollution control systems and industrial fans. Our team works closely with you to ensure that every solution is optimized for efficiency, cost-effectiveness, and long-term sustainability. Whether you're upgrading an existing system or developing a new one, we provide expert guidance and innovative solutions to help you succeed.

Computer Aided Design (CAD)

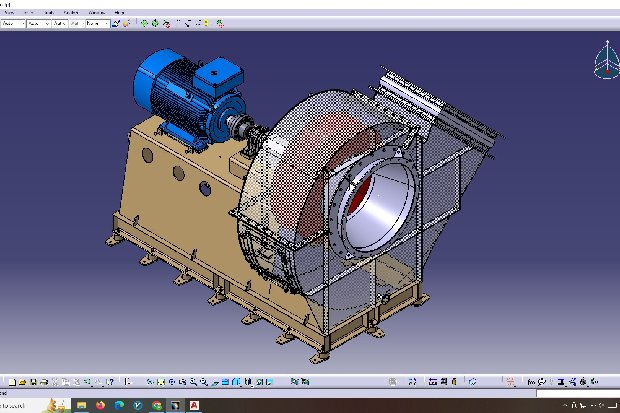

Our CAD services provide specialized support in the development, design, and manufacture of filters, dust collectors, and industrial fans for air pollution control systems. We assist you in modeling highly detailed 3D CAD models of complex components, including filter housings, dust collector parts, filter media, support structures, and industrial fans such as centrifugal and axial fans. Our precision-driven approach ensures that every component of your system is designed to meet your exact specifications, enhancing the overall performance and reliability of your air filtration and ventilation systems.

For industrial fans, we apply our expertise to create detailed models that account for critical aspects like airflow, pressure, and material stress. Whether you require fans for heavy-duty industrial applications or more precise models for specialized systems, our team ensures that all fan components are designed for optimal performance and efficiency. From fan blades and rotors to housings and shafts, every part is modeled to provide maximum airflow while minimizing energy consumption and noise.

Our technical drawings provide clear and detailed dimension sheets or production drawings, ensuring that each component is fully understood and ready for manufacturing. These drawings include all necessary dimensions, material specifications, and assembly instructions, allowing for a smooth transition from design to production. Our focus on accuracy and completeness guarantees that all essential information for production, assembly, and quality control is included, reducing errors and improving system integration.

We offer our CAD services in both English and French as standard, and we can also provide support in additional languages upon request. For the exchange of CAD data, we work with a variety of file formats, ensuring smooth integration with your existing systems and enabling collaboration with your engineering teams, regardless of the software they use.

Whether you're designing new filters, dust collectors, or industrial fans, or optimizing existing systems, our CAD services ensure that every component is built for durability, efficiency, and high performance. With our advanced CAD capabilities, we help you create reliable filtration solutions and industrial fans that meet the highest standards of air quality and energy efficiency.

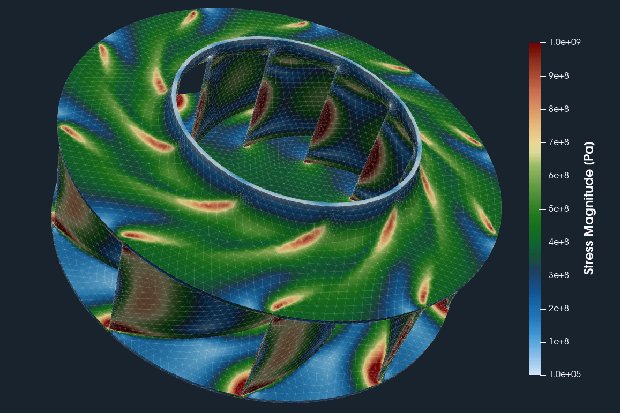

Finite Element Method (FEM)

The Finite Element Method (FEM) allows for a detailed and precise analysis of the structure and dynamics of your industrial fan systems. Our experienced engineering team uses the latest simulation software to optimize the performance, strength, and reliability of your equipment. With FEM, we can model complex physical phenomena such as stress, strain, vibration, and thermal behavior within your fan systems, allowing us to predict their behavior under real-world conditions.

FEM plays a crucial role in ensuring that your fan systems are designed to perform efficiently, safely, and reliably. By simulating various operating conditions and external forces, we can identify potential weaknesses, optimize designs, and validate system integrity before production or installation. This helps you avoid costly errors, reduce maintenance, and increase the overall lifespan of your equipment.

Our FEM services are not just about improving performance; they’re about enhancing the durability and efficiency of your systems. Whether you're developing new fans or optimizing existing ones, our FEM simulations give you the insights necessary to make informed decisions that lead to better results.

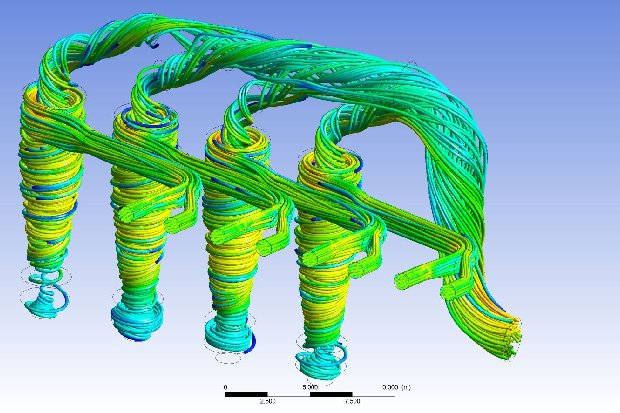

Computational Fluid Dynamics (CFD)

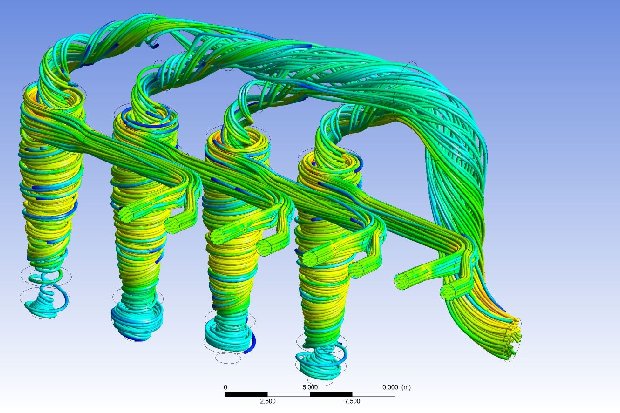

Computational Fluid Dynamics (CFD) is a powerful tool that allows for detailed analysis and optimization of the flow dynamics within your fan systems and air pollution control systems. Our experienced engineering team utilizes advanced simulation software to maximize the performance, efficiency, and reliability of your systems. We provide numerical flow simulations to calculate and optimize installations, whether they are manufactured by us or third-party suppliers.

Through CFD, we can simulate a wide range of systems, from electrostatic precipitators and bag filters to venturi scrubbers, complete gas duct systems, and industrial fans. We tailor our analysis to meet the specific needs of each project. Our process begins with recalculating the geometry of your existing systems. By simulating the flow dynamics around and through the equipment, we assess critical parameters such as velocity, pressure losses, and flow patterns. This helps us identify inefficiencies and areas for improvement, enhancing the overall system performance.

In addition to recalculating existing geometries, we also focus on the optimization of fan geometry. Using CFD simulations, we can redesign or adapt components such as fan blades, inlets, outlets, and ducts to maximize flow performance. We analyze and compare different design variants to find the most efficient configurations, which reduce energy consumption and improve operational reliability.

With our years of experience and state-of-the-art simulation software, we understand the critical factors involved in optimizing airflow and improving system performance. After conducting CFD analyses, we provide detailed reports outlining potential optimizations and can implement these changes ourselves, ensuring a seamless transition from analysis to implementation. Whether it's a simple optimization or a complete redesign, we help you achieve the highest level of performance and efficiency for your fan and dedusting systems.

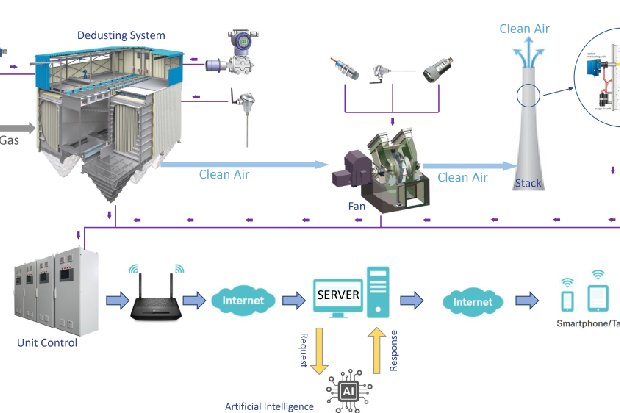

Remote Control & AI Technology

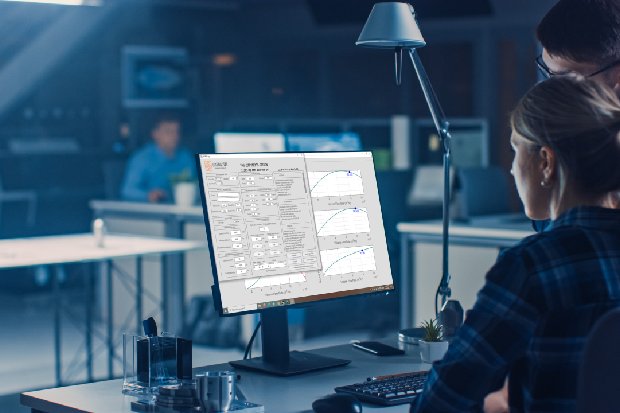

At Air Fractal, we are committed to ensuring the continuous performance and reliability of your air pollution control systems and industrial fans, and we understand that uptime is critical. That’s why we offer advanced remote monitoring services to keep your systems running smoothly 24/7. With our remote data transmission technology, we are able to perform ongoing diagnostics, giving us real-time visibility into the status of your systems at all times. By using specialized sensors and cutting-edge visualization equipment, we monitor system-specific process parameters and functions. This allows us to instantly identify potential issues, enabling us to take corrective actions and introduce optimization measures at any point.

The benefits of remote monitoring are clear – it minimizes system failures, reduces downtime, and ultimately helps you avoid costly production losses. Our approach not only helps in early detection of faults but also supports predictive maintenance, ensuring that any necessary adjustments are made before problems occur, further extending the life of your systems and improving their overall efficiency.

In addition to remote monitoring, we are proud to offer our proprietary AI-driven technology, which takes system management to the next level. This cutting-edge technology provides factories with a fully externally monitored air pollution control system, giving them access to real-time data on the condition of their air filters. The AI system continuously analyzes this data to assess the state of the filters and suggests quality control measures that can improve their efficiency. By implementing these insights, we can help increase the lifespan of your air filters, ensuring they remain effective for longer periods, and ultimately reduce maintenance and replacement costs. The result is not only enhanced system performance but also significant reductions in overhead costs, providing both short- and long-term savings for your business.

Measurement & Testing Services

Dust Collector Performance Testing and Measurement

At Air Fractal, we provide comprehensive testing and measurement services to ensure the optimal performance of your dust collection systems. Using state-of-the-art equipment and our years of expertise, we evaluate key performance indicators such as airflow, filtration efficiency, pressure drop, and particle collection efficiency. Our team conducts thorough tests to verify that your dust collectors operate at peak efficiency, reducing energy consumption and minimizing environmental impact.

We perform detailed measurements on-site or in our specialized test facilities, depending on the size and complexity of the system. For each dust collector, we assess parameters such as the distribution of airflow across the system, the effectiveness of the filtration media, and the overall efficiency of particle capture. Our testing ensures that your system is compliant with environmental standards and delivers reliable, cost-effective performance.

The results of our performance testing are compiled into a comprehensive report, which includes recommendations for optimizing the system and maintaining its long-term efficiency. This detailed documentation provides full traceability, ensuring that all performance metrics are met and that your dust collection system operates safely and effectively.

Fan Performance Testing and Measurement

At our advanced test and measurement center, we leverage our extensive experience to assess the natural frequency and resonance ranges of your industrial fans, preventing potential damage. By thoroughly analyzing the entire drive system—including the fan, motor, and inverter—we ensure compliance with permissible vibration limits as per ISO 14694 and DIN ISO 20816-3 standards. For systems up to 250 kW, measurements are conducted on our in-house test bench, while for higher power ratings, we perform measurements directly at your site. The detailed parameter reports are included in the final documentation, ensuring full traceability and adherence to the highest quality standards.

Consulting

At Air Fractal, we provide expert consulting services that cover every phase of your industrial fan and dust collector systems. From initial consultation and system design to installation and ongoing maintenance, our comprehensive services ensure that your equipment operates at peak performance throughout its entire life cycle. We work closely with you to understand your specific requirements and provide tailored solutions that optimize airflow, enhance filtration efficiency, and improve overall system reliability.

Whether you're designing a new fan system, improving the performance of an existing dust collector, or ensuring compliance with environmental standards, our expert guidance is essential for achieving long-term operational success. Our team supports you in every step of the process, ensuring that both your fans and dust collectors are optimized for maximum efficiency, cost-effectiveness, and minimal downtime.